Every customer's wishes are different. That's why our partners don't get off-the-peg offers, but services precisely tailored to the respective situation and task.

- analysis of the requirements

- elaboration of the layout

- analysis of interfaces and possible risks

- pre-planning of the project

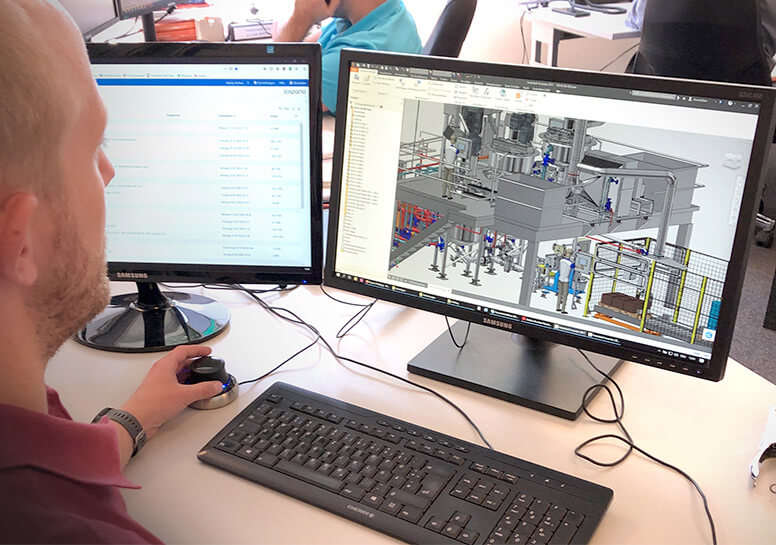

According to detailed specifications or concrete requirements of the customer, the designers and engineers create detailed models in 3D technology. The computer-aided design is carried out using the latest hardware and software, including the AutoCAD software Inventor.

- elaboration of concepts

- layout of plants

- simulations based on models

- cycle time analyses

- analytical and FEM calculations

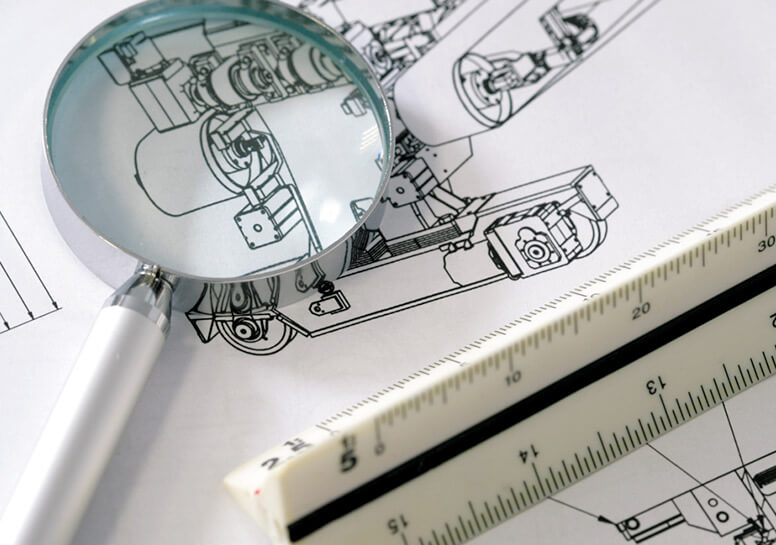

- 2D drawings and 3D models

- technical documentation

- description of the equipment

- operating and maintenance instructions

- CE documentation

- hazard analysis and assessment

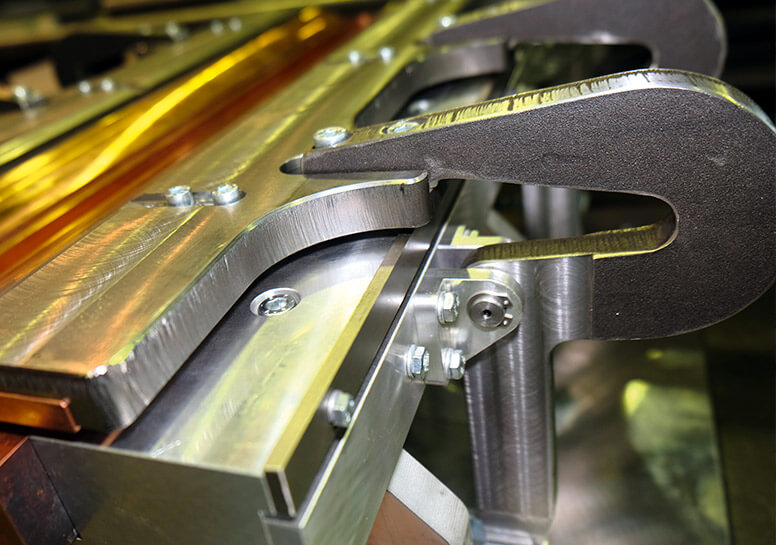

Precisely manufactured components on schedule form the core of every project: the assembly/plant itself. KICK Group manufactures on both conventional and state-of-the-art CNC machines.

- component and assembly production; also on the basis of customer drawings

- mechanical processing, also of large parts

- welded structures and steel construction - WHG and EN 1090 certified

- construction of foundations, platforms and barrier areas

- spare parts, components

Are you overhauling your production line or other areas of your plant? We dismantle the relevant plant components, overhaul functional parts that remain in the plant and dispose of what needs to be disposed of.

- dismantling

- modernising and reconditioning of functional parts

- disposal of steel scrap

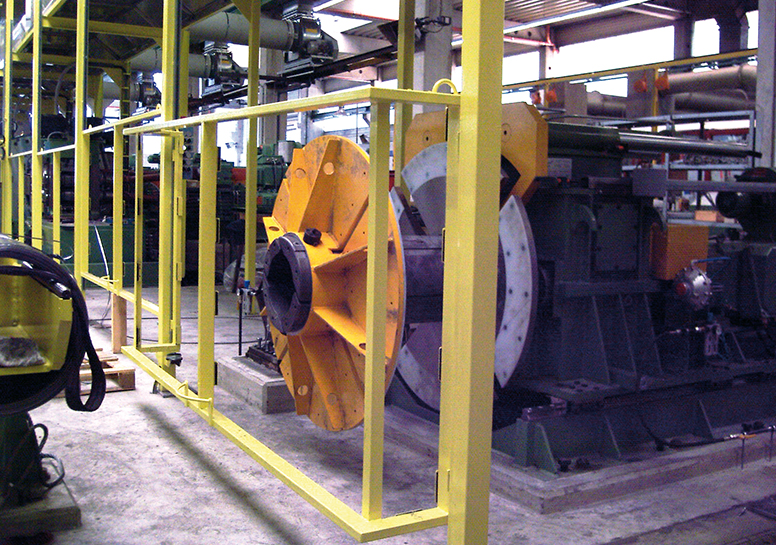

When modernisation and repair work is due in large production lines, it can be very stressful. Every minute of non-production costs money; a lot of money. That's why you need to be able to rely on your partners 100%. KICK Group has many years of experience in this field. With experienced project managers, foremen and assemblers, the installation succeeds on schedule, so that your plant is productive again as quickly as possible.

- pre-assembly of plants with components manufactured by us as well as standard and purchased parts procured by us (gears, bearings, etc.)

- assembly of new plant sections

- integration of new plants into existing plants

- installation and integration of the necessary control and automation technology

In order to ensure a smooth start of your new plant, KICK Group also accompanies you beyond the installation until you are back in normal operation.

- commissioning support

- test runs

- readjustment

- handover