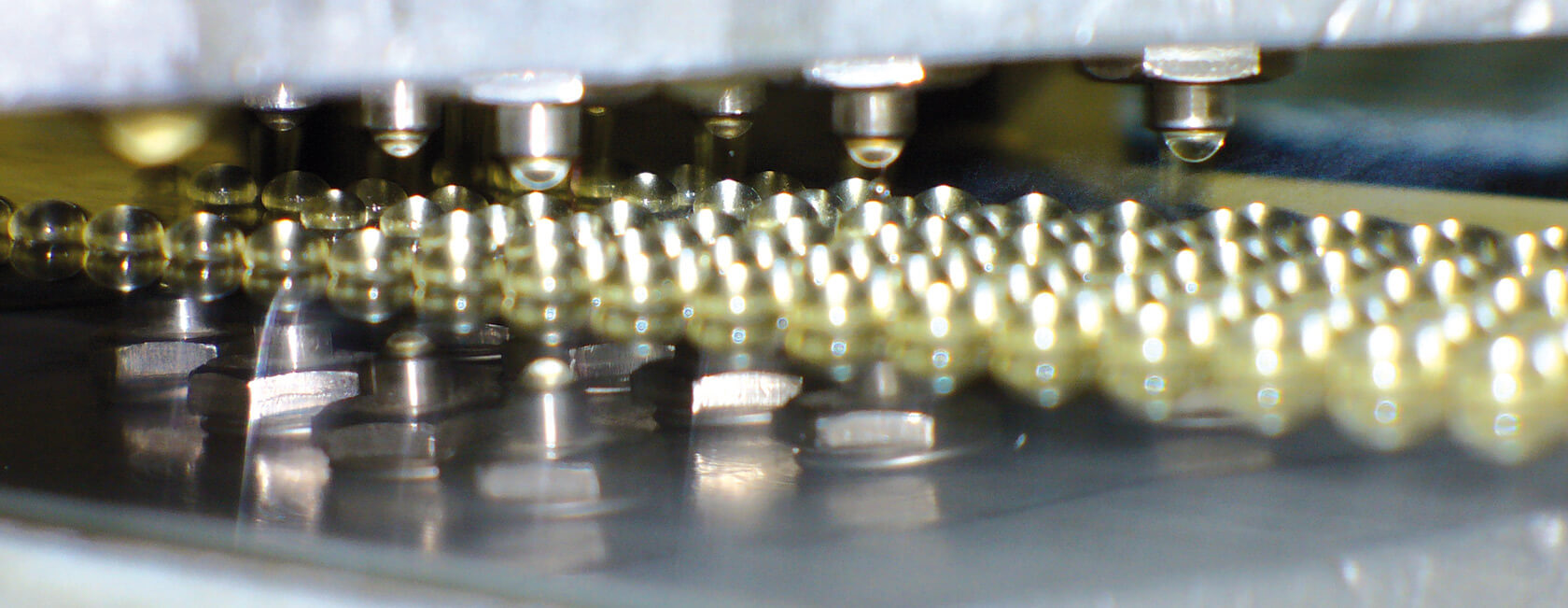

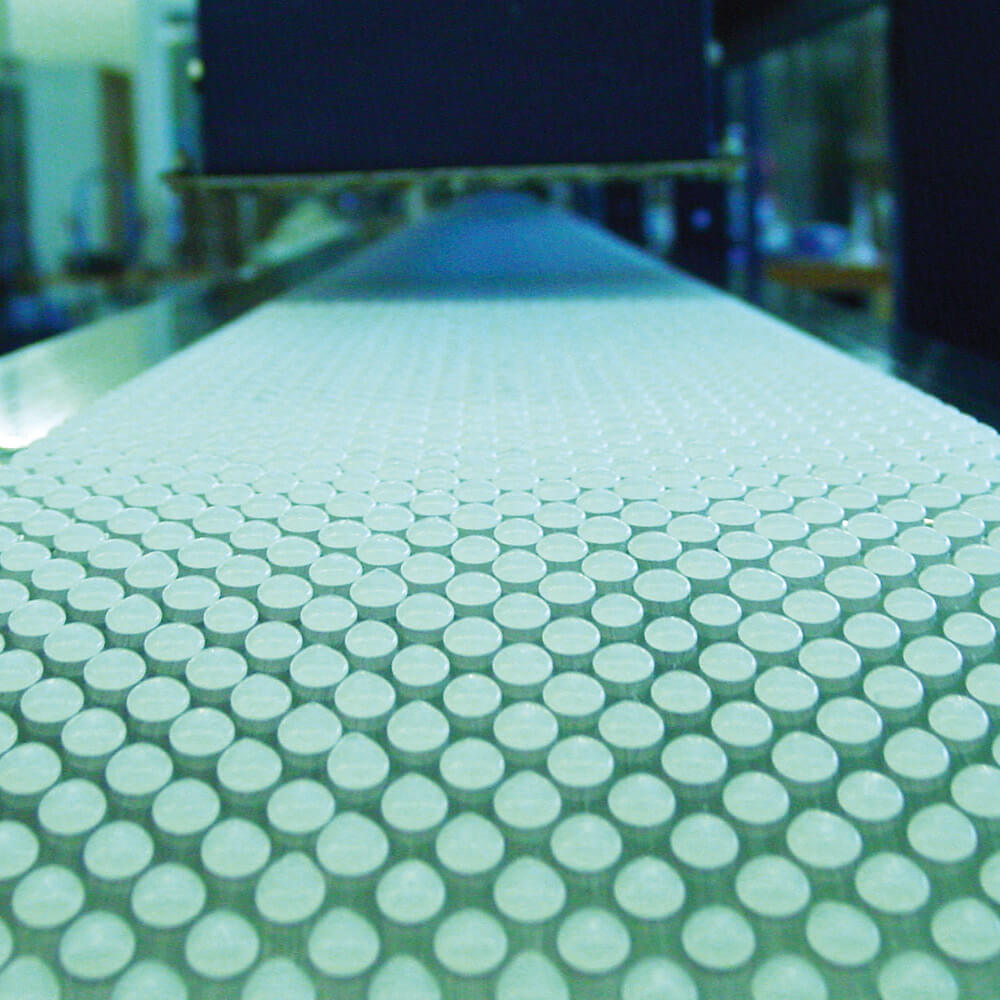

Take a molten product and turn it into granules that are round, dust-free and thus ideal for packaging, weighing and transport. - the pastillation process is finished. And thus the core of KAISER Process and Belt Technology.

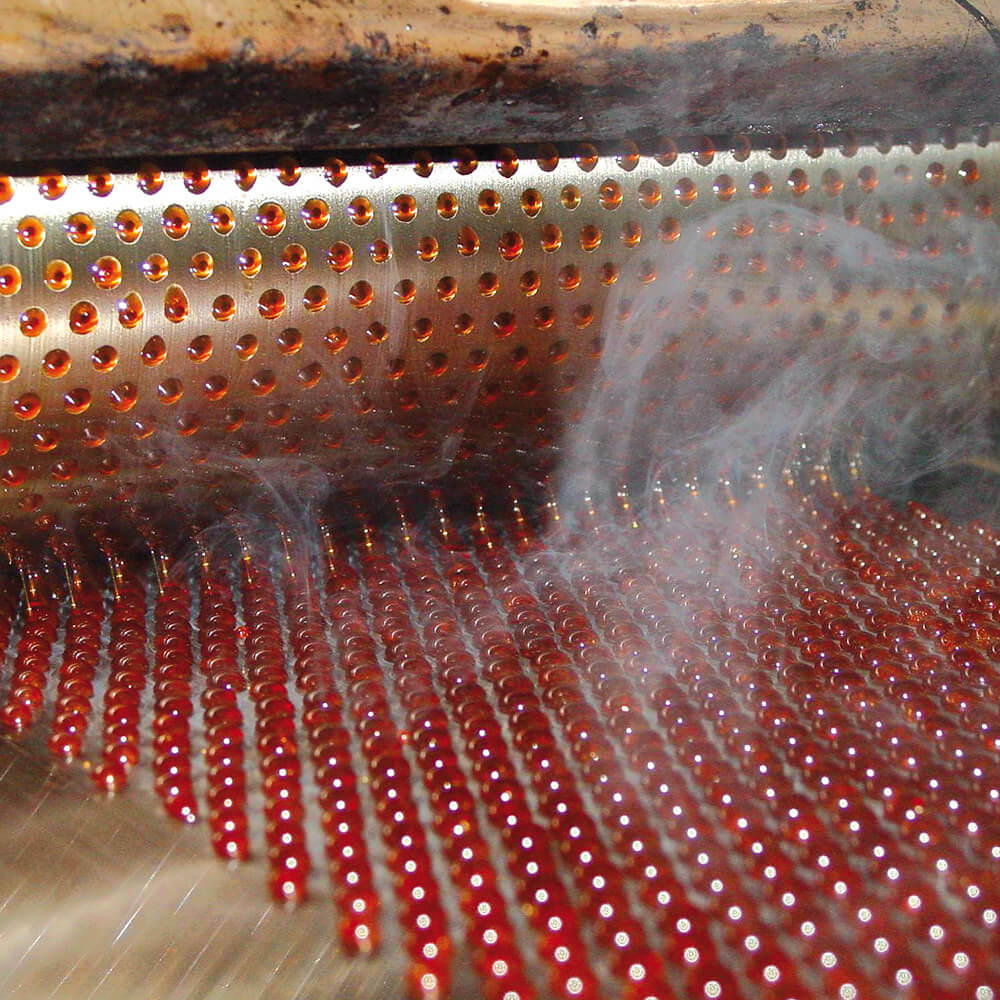

More than 75 years ago, the company's founders were the first in the world to apply for a patent for this very effective, inexpensive and simple process for continuously converting a molten product into granules. The experience and process engineering know-how gained over the decades put us in the unique position of being the only company in the market to offer several different pastillation processes and thus cover the complete range of all products that can be dripped: from thin, crystalline melts to highly viscous polymers.

We supply equipment for corrosive products, for melts with solid fillers or for substances that tend to supercool, ... In addition to pure pastillation plants, we also offer strip pelletising plants and plants for the production of flakes as well as double belt coolers.

We always regard the cooling belt system as the heart of a complete system - and supply the other components of the turnkey "package unit" as required. Reactors, mixing and intermediate vessels, pumps, filters, piping systems, silo, bagging and palletising equipment or the supply of the unit with heating and cooling medium: we are the #pioneersofpastillation. And much more!

Based on more than 75 years of experience, we work with a wide variety of processes, which we optimally adapt to the process and the end product, depending on the requirements. Our in-house test centre and the huge archive help us to do this.

KAISER Process and Belt Technology GmbH

Siemensring 54-56

47877 Willich

Germany

Tel.: +49 2154 89107 – 165

Mail: hoefler@kaiser-pbt.de

Website

Website